Apollo Solar designs and manufactures energy systems for Remote Mobile Telecom Towers. Starting in September 2012, Camusat has installed these systems on towers owned by Orange. With over 1,000 systems now running, some for the entire six-year period, the results in terms of reliability, cost, battery life and greenhouse gas avoidance are statistically significant. The installations are spread over seven countries in Africa, which include challenging climates. This case study, submitted by Apollo Solar CEO John Pfeifer, will identify the principle results, and comes at a timely moment as MNOs and towercos contemplate the economic, social and regulatory burdens associated with continued reliance on fossil fuels.

Overview

All mobile phone towers, or Base Transceiver Stations (BTS) require continuous electricity. Utility grid power may not be available outside urban areas in many emerging markets. As the coverage for mobile phones grows in more and more rural areas, a larger percentage of the towers depend on remote energy systems. At first, the easy answer was to install a diesel generator at the base of every tower. However, diesel generators (DGs) come with five inherent disadvantages:

1. The cost of diesel fuel is significant, and the cost of delivery to remote sites make diesel fuel more than 50% of the total operating expense for every remote tower.

2. The poor reliability of diesel generators is such that two generators must be installed at each tower to approach the continuous energy requirement.

3. The generators require that oil and filters be changed every 250 hours, which means a visit to the remote sites every ten days. The entire generator is typically replaced or rebuilt every 18 to 24 months.

4. Carbon dioxide and the other greenhouse gases created with the burning of diesel fuel for electricity at telecom towers are now understood to represent a significant part of the cause of climate change.

5. Diesel fuel often gets stolen at multiple points in the supply chain. Theft was been estimated as high as 30% by many tower companies.

Relevant backgrounds of the three participating companies

Orange was experiencing the same problems as other Mobile Network Operators with diesel powered cell sites in their network. The costs of diesel powered sites at Orange may have been more significant because their networks were expanding into rural sections of African countries where electric grids were almost non-existent and the remote solution was becoming a larger percentage of the total network energy requirement.

Camusat had been contracted by France Telecom (now Orange) to build and install towers for many decades. They have a strong relationship and both companies are leaders in their field, so it was just a small step in the right direction for France Telecom to ask Camusat to take the added responsibility of providing the solar-powered energy systems required on the remote towers.

Meanwhile, Apollo Solar, Inc. had deployed solar-based energy systems for off-grid military, telecom, and commercial applications in challenging climates, and had developed a line of energy systems specifically for remote telecom towers.

In the image at the top of this article, a typical Apollo Solar Cabinet is shown installed under a standard Solar Array. The tan colored boxes house the batteries. These three components comprise the complete pure solar remote energy system for a BTS, drawing about 1.5kW.

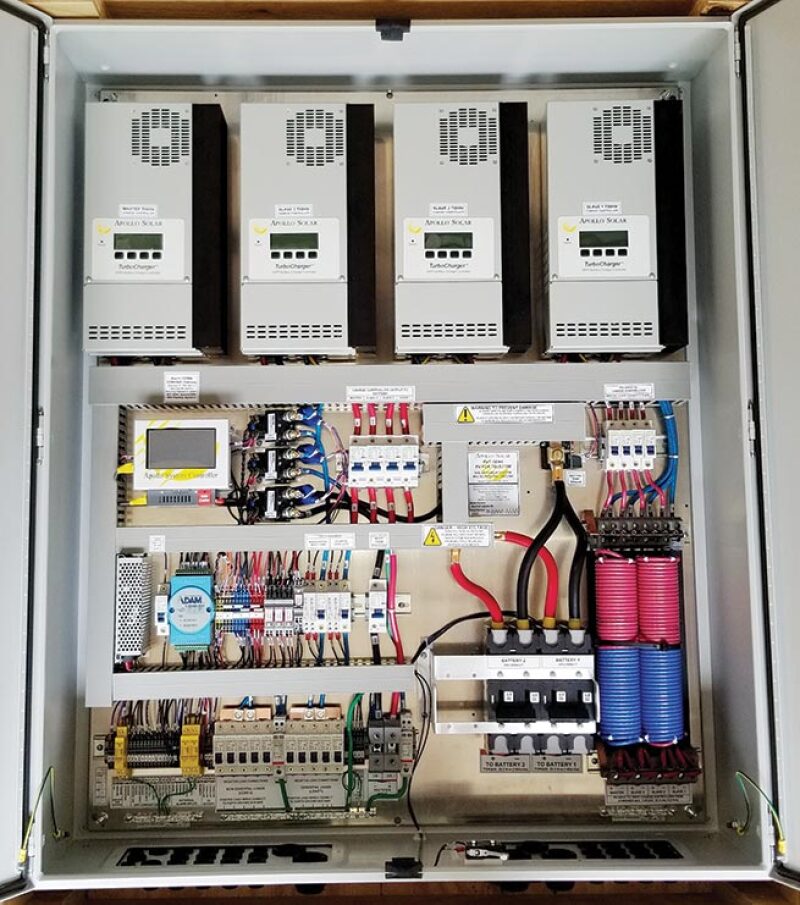

Inside the Apollo cabinet for 20kW of PV

The Apollo cabinet includes all of the circuit breakers, connections, relays and contactors required for complete operation. In addition, we have integrated the sensors, the computer and the modem, which make up the remote monitoring system.

The cabinet is only 1,000mm wide by 1,200mm tall by 300mm deep and has an ingress protection rating of IP65, so no dust or moisture can get in.

By 2010, Apollo had a number of pure solar systems deployed on telecom towers in North and South America. In the process of supporting these remote systems, Apollo developed the Remote Monitoring System, which sends all the key operating parameters back to a server in Apollo’s Network Operating Center in real time. Feedback gathered from the remote sites provides key insights to enhance the reliability of every part in the system.

Uptime

In the tower energy business, one of the critical success factors is uptime. Typically, the company providing the energy is under a Service Level Agreement that imposes a penalty if the energy availability uptime is less than 99.97%. The exact level varies from contract to contract, but we were told that any downtime in excess of a few hours per year is charged back to the energy provider at the rate of sometimes $30,000 per hour!!! Clearly the highest priority must be placed on reliability. When just a single hour of downtime can cost more than a new system, having a proven track record is essential. Because the electronics are the most vulnerable part of these systems, attempts to cut costs in the electronics cabinet is generally deemed a false economy.

The risks associated with solar energy systems

When this programme began in 2011, the telecom industry was skeptical that a pure solar energy system could be designed, built and installed in the challenging climates of Africa that would yield the kind of reliability that telecom towers required. Several MNOs had experimented with small-scale solar added to a diesel generator-based system. The results of these experiments varied from poor to worse. Since the results of these failed experiments were rarely published, it was not easy for us to get hard data. However, from our understanding inside the industry, Apollo obtained these essential facts.

The majority of these “experimental” solar sites were naively built with inherent fatal flaws. The sites used for these solar experiments were required to continue to provide uninterrupted power, so the diesel generators were retained to produce most of the energy. The small amount of solar that was added was done using solar arrays and batteries that were undersized, and they used the cheapest possible, untested electronic equipment. In the face of the challenging climates, it is no surprise that results from the majority of these experiments were disappointing. Some MNOs and tower companies came to the erroneous conclusion that solar would not work in their environment.

In the 2010 - 2012 timeframe it was considered a risk to install solar for remote energy systems, and a much larger risk to eliminate the generator entirely to depend only on solar. For all the reasons stated, the equipment for a pure solar site was under tremendous pressure to work without failures, because there was no backup.

The challenge presented to Apollo Solar

Orange and Camusat asked Apollo to take on some of the risks associated with deploying pure solar remote energy systems. Considering the history of the failed hybrid experimental solar power systems, and the penalties for downtime, these risks were rather daunting. Certainly Orange and Camusat were taking on a large portion of the risk, however both of these partners were large enough to survive any failures at a certain number of sites, and diesel generators could be re-installed if failures occurred. There were several individuals at both Orange and Camusat who put their reputations on the line. Apollo Solar however was a smaller company and therefore more vulnerable.

Batteries and PV modules had been proven in other fields, so they were not an issue. The electronic equipment Apollo Solar was to supply was considered the weakest link because electronics can fail with heat, or cycles of hot and cold ambient temperatures. The Apollo Solar equipment had to be designed to withstand extremes in temperature and full temperature cycles every day without a system failure over many years. Most specifications for military electronics are less robust.

Apollo Solar accepted the challenge and employed the full spectrum of our 40 years’ experience from our parent company, Electronic Design Lab, Inc. Our high reliability design uses these four elements:

1. The design of the pure solar energy systems for Orange and Camusat used the core T80HV MPPT Solar Charge Controller, which Apollo Solar had designed and tested for extreme ambient temperature duty. Apollo had had thousands of units in the field in challenging climates for over five years at that point and the reliability was well proven.

2. To enhance the reliability as much as possible, Apollo designed the telecom energy systems with redundant channels of T80HV Charge Controllers. Redundancy is a well-known design method to maximise reliability. Statistically, in parallel systems, the chances of two channels experiencing a failure at the same time is extremely small. In all cases there would be at least two and in many cases, three or four T80HVs running in parallel. They are each smart enough to run as totally independent units, so if one were to fail, it does not affect the others.

3. The pure solar remote energy systems are battery based and Apollo made certain that each system used multiple parallel strings of batteries, and that every battery system was large enough to provide all the energy required for the telecom BTS load for at least three days without any energy input.

4. Finally, Apollo Solar integrated our Remote Monitoring system in each Cabinet. Our software reports the status and any alarms or warnings automatically every minute. So if any parameter were to drift out of the acceptable range, the central office or NOC was instantly aware and a crew could be deployed to the site to address small problems before they became big enough to cause down-time.

Case study details

Of the 1,000+ systems installed starting in September 2012, there has been a total of 0.0 hours of downtime. The key is that Apollo Solar designed these systems with 100% uptime reliability as the first priority without compromise. So every active component in the energy path has redundant components in place. Active components are those parts with silicon semi-conductors that are in a switching state and produce heat. Passive components are items such as circuit breakers, connectors, wires, fuses, relays and contactors usually without silicon. Passive components have track records of very low failure rates and are not as sensitive to temperature extremes.

The most critical electronic components are the Solar T80HV MPPT Charge Controllers because they use many active semi-conductors. Each system uses a minimum of two Charge Controllers running in parallel. Many systems have three or more. The critical BTS load is connected directly to several parallel strings of large 48-volt lead-acid batteries. The batteries are monitored carefully to make sure they are being charged properly. If remote sensors indicate the state of charge is trending low, alarms are sent out so field technicians can be deployed to fix any problem. The batteries have at least three full days of autonomy.

That said, Apollo Solar makes it clear that, in the course of this case study, there were failures of the Charge Controllers. In fact, 22 Apollo Charge Controllers were returned with internal failures. Of the 2,500 Charge Controllers in the study, 22 units represents 0.88%. Because each of these Charge Controllers was wired in parallel with at least one other Charge Controller, the second unit continued to work when the twin failed so that the energy system did not fail and the power to the site was never lost. The offending Charge Controller was replaced during regularly scheduled maintenance visits so there was no additional maintenance cost associated with this redundancy feature. A complex component that shows a failure rate of less than 1% over the long term is considered acceptable since none of those failures caused the systems they were powering to go down.

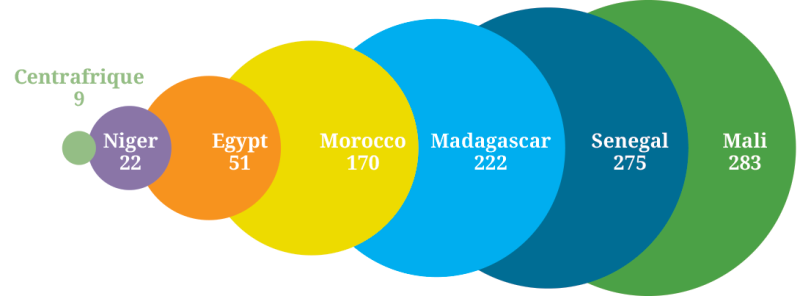

Sites with Apollo Solar pure solar systems installed (as at September 2018)

Locations of the Apollo Solar sites in Africa

Priorities from now until mid-century When this programme was initiated, the focus was on reliability and cost. The capex was compared against the opex of the pure solar, diesel only as well as diesel / battery hybrid. The total cost of ownership (TCO) was calculated for each design in order to compare capex and opex using the TCO over the time frames of five, ten and 20 years. Priority was given to the elimination of fuel theft and the minimising of other diesel-related costs.

At the onset of this programme the world’s understanding of the Climate Change Crisis was not what it is in 2019. The telecom industry in Africa had been fully focused on the financial costs of diesel-generated electricity. Today, the highest priority is increasingly weighted on reduction of fossil fuel use whenever and wherever possible. In the light of new Greenhouse Gas (GHG) facts, other case studies have shown that BTS towers along with the data centres associated with the smart phone revolution, are responsible for a large use of electricity which generates as much GHG as the transportation sector. Our case study now takes on a new significance. By using pure solar to charge the batteries, the diesel generators were totally eliminated and every one of these 1,000 sites has a zero carbon footprint.

Case study results: Greenhouse gas avoidance

Calculating the GHG avoided for telecom towers is straightforward because the load is well known.

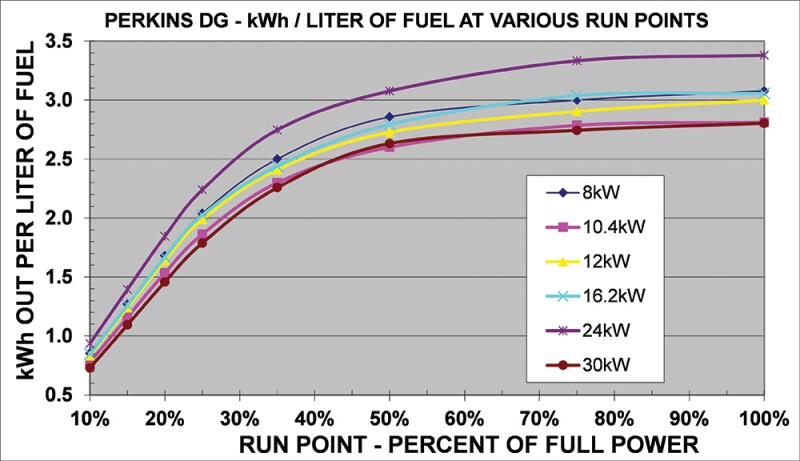

The diesel generators used on a BTS are an average of 12kW. Based on the specifications of the popular diesel generators made by Perkins, we find that the efficiency for producing electricity is much lower when running below 50% of full load. Most BTS Towers use oversized generators because they are large and difficult to steal. A 12kW generator running at 10% of full power gets only 0.833 kWh per liter of fuel.

The amount of CO2 resulting from combustion of diesel fuel is a fixed rate of 2.639 kg per litre of fuel by the laws of chemistry. Diesel fuel burns completely meaning that essentially 100% of the carbon is combined with oxygen in the oxidation reaction. The weight of a Carbon atom is added to the weight of two Oxygen atoms. The other greenhouse gases add to the global warming, but we focused on the largest (81%) offender, CO2. The size, percentage of full power or efficiency of the generator make no difference: every litre of diesel fuel is going to produce 2.639 kg of Carbon Dioxide.

It is simple arithmetic to find the amount of CO2 produced by each DG:

- The energy required for a 1.2kW BTS load running 24 hours is 28.8kWh per day.

- At 0.833kWh per liter, the generator fuel consumption is 1/.833 or 1.20L/kWh.

- The amount of fuel burned each day is 1.20L/kWh X 28.8kWh which is 34.56L per day.

- Finally, 34.56L per day X the given of 2.639 kg of CO2 per litre of fuel is 91.207 kg of CO2 per day, per site. Or 2,774.5 kg per month, per site.

So, by completely eliminating the diesel generator, the pure solar sites avoid all of the 2,774.5 kg of CO2 for every 1.2kW load site, every month.

Diesel generator energy output running at various percentages of full power

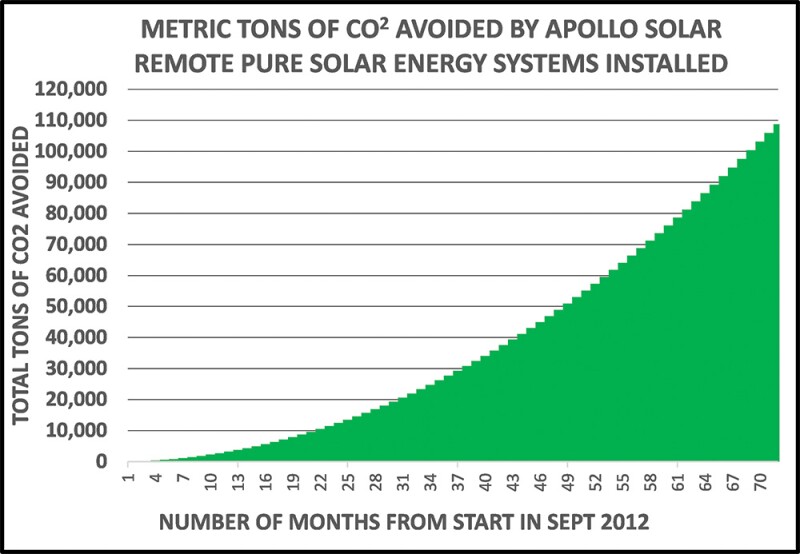

Although the 1,000+ Apollo pure solar remote energy systems were installed in batches from September 2012 to April 2018, we can average the installations on a relatively continuous basis, which is about 15 systems per month for 67 months. The graph below shows the total amount of CO2 avoided each month during this six-year case study. Each month 2,774.5kg of CO2 X 15 new sites which is 41,617.5 kg is added to the running total. One can see that at the end of the 72 months of this study, we have avoided a total of almost 110,000 metric tons of CO2. Without installing any additional systems, the installed systems continue to avoid an additional 2,788 metric tons of CO2 every month going forward.

For international clarity, a metric ton (1000 kg) is 1.1023 U.S. ton (2000 US lbs) so the 110,000 metric tons on the chart is equal to 121,245 U.S. tons.

Cumulative metric tons of CO2 avoided by the Apollo pure solar systems

Case study results – opex v capex and the TCO

The bottom line is that these new solar energy systems have to compete against the costs of diesel generated electricity.

In order to compare these costs of solar and diesel it is essential to understand that the solar energy systems are primarily a single up-front costs, often a capital expense, to purchase and install the equipment. The ongoing costs for fuel and maintenance, or operating expenses of a pure solar energy system are very close to zero. The batteries are costly and have a finite cycle life at between five and ten years. The typical DG plant costs are very different from the Solar plant. The up-front capex for diesel is lower than solar. Each generator costs about US$15,000 installed (the costs of each item vary from country to country). With two generators and the fuel tank, the complete energy system might be US$35,000. The ongoing opex for diesel is very high. The costs include the fuel transported to each site, maintenance visits to change oil and filters every ten days, and replacement of the generators every two years. It is this opex which the new solar based systems had to address.

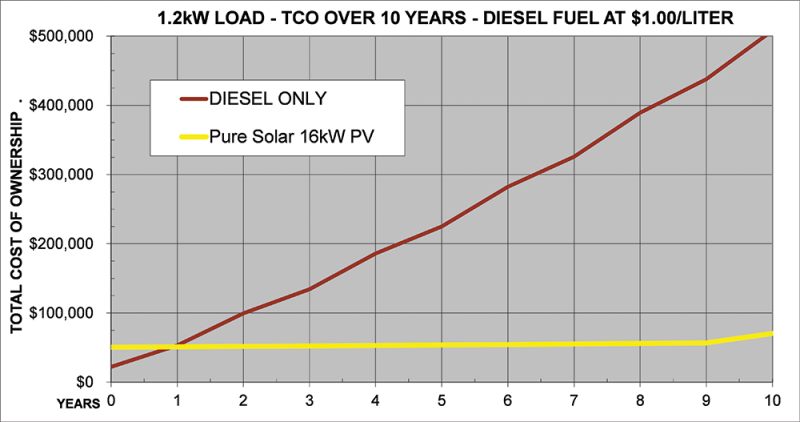

In order to compare capex, which is a one-time cost, with opex items, which are ongoing, we convert both items to Total Cost of Ownership (TCO) over time. See the TCO chart. When the absolute cost of the pure solar system crosses the line representing the costs of the DG site, the pure solar system has paid for itself and for the rest of its life-time, it is free of costs with the exception of battery replacement which is about every ten years.

The results of this case study show that the TCO of solar energy systems are lower than DGs after one to two years. The length of time to “payback” is determined by many factors, but the costs of the diesel fuel delivered to the sites is the most significant factor.

TCO – Pure solar and diesel generator for 1.2kW load

Looking forward – can the future costs be predicted?

We recorded the price of solar PV modules and price of diesel fuel over the course of this case study.

The capital cost of Solar has come down. The price of silicon solar modules dropped from US$1.75/watt in 2010 to US$0.35/watt in 2017. It is now just 20% of what it was in 2010 and is relatively consistent. The point is that since a pure solar system is essentially a capex issue, the cost can be financed at a fixed cost per month for a fixed number of months. So the cost of energy is flat, well known, and goes to zero at some point.

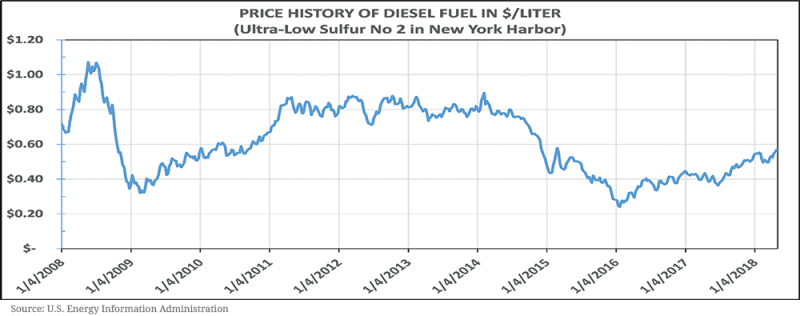

Contrarily, the cost of diesel fuel has been volatile and without predictors. The base price in New York Harbor is directly related to the global price of a barrel of crude oil. On any day the price in $/litre of Ultra-low sulfur No. 2 diesel in New York Harbor can be found by dividing the global price of Brent Crude in $/bbl by a factor of 132.6.

Variability by country adds another factor. When a litre of diesel at the pump in the U.S. was $0.65, the price in Norway was $1.63 and $0.12 in Saudi Arabia. In Sub-Saharan Africa the average price was about $1.15. The cost of delivery to each remote site is a variable that cannot be addressed in this paper, but TowerXchange reports that the delivered cost of diesel is amplified as high as 1.8x in logistically challenging markets like the DRC. A contract with the fuel delivery company may address some of these variables, but the theft is still a large unknown.

An Energy Services Company (ESCO) is running a high risk if they are using diesel fuel to generate the electricity they are selling at a fixed price.

Price of diesel fuel

Results – were the risks worthwhile?

Yes, the results of this programme prove that the risks were worth taking. There are four areas that stand out:

1. Reliable energy: This programme proved that pure solar remote energy systems can be deployed in the challenging climates in Africa and are perfectly reliable. In fact the uptime reliability far exceeds that of the DG systems that have been the mainstay for many years.

2. Total Cost of Ownership: This case study indicated that the TCO of the pure solar systems is significantly lower than the DG based systems after the initial period, which is 12 to 36 months depending on the real costs of the diesel fuel and other factors.

3. Carbon Dioxide avoidance: Most significantly, it is easy to prove that the pure solar remote energy systems deployed and described in this case study avoided a significant amount of Carbon Dioxide and other greenhouse gasses, which would have been dumped into our atmosphere if DGs had been used instead of pure solar systems.

4. Elimination of fuel theft: Using only solar for remote energy is the most effective and lowest cost method to eliminate the theft of diesel fuel.

Conclusions

There is no question about the relationship between burning diesel fuel and the generation of CO2 and other greenhouse gases. And there is no question that the use of diesel fuel will be limited by the carbon tax or some other constraint according to the Paris Accord and other international agreements. The only question is how soon these financial constraints will impact the ESCOs, the tower companies, the MNOs and the rest of our industry. It is up to the stakeholders in the global tower industry to get ahead of the rulings (and on the proper side of history), or be dragged along paying the carbon tax because of non-compliance with the Global Committees and with moral common sense.

Using solar power for remote energy systems is an easy, reliable solution that pays for itself and continues to cut operating expenses. Apollo Solar has removed the risks and has proven that the pure solar energy systems are most cost effective, most reliable and most eco-friendly type of energy generation system for remote telecom tower sites.