To date, monitoring of workforce activity on cell sites has been reliant on the use of disparate systems, paper records and word of mouth. Acsys, best known in the telecoms sector for their access control systems, is now expanding their focus to develop a platform which integrates access data with data points from multiple third party systems, offering infracos the opportunity to better track activity and productivity on site. TowerXchange spoke to Acsys’ Michael Sothan to understand the platform, what data it can capture and how it is set to revolutionise productivity at telecom cell sites.

TowerXchange: Please can you provide an introduction to Acsys and why they are now looking to expand beyond access control?

Michael Sothan, Vice President, Americas, Acsys:

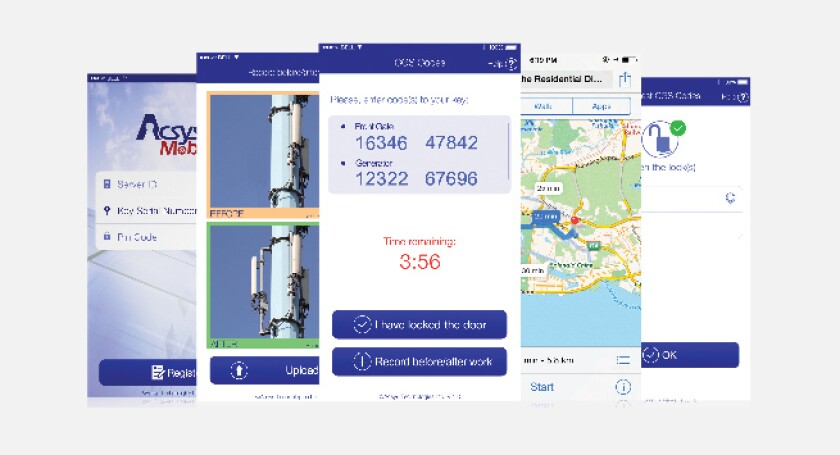

Acsys was originally a general access control and workforce management solution provider. In the company’s early days we did a lot of work with the government and military sectors but after seeing a strong fit in the telecom infrastructure space, we developed a telecom-centric access control and workforce management system specifically for the sector which has now become well recognised by the industry.

Whilst security is always a concern for tower owners, and we are aware of very high rates of vandalism in some Latin American countries like Brazil, the market is shifting towards an increased focus on efficiency and opex reduction. With customers demanding ever more data at lower costs, ARPU is being driven down and capex on the increase operators are putting more focus on their bottom line, looking at ways to make savings.

In order to improve efficiency on site one must first understand what is happening on site; to date it has been hard to get a clear picture on this. There has been a real lack of data detailing what is going on – even to the extent of knowing for certain whether a job has actually been done! If a job is being done, it is useful to know factors and metrics such as when it was done, who did it, how long it took, did it take longer than it has in the past? When you start to obtain and interpret this data you start to develop a meaningful picture of site operations.

Operators deploy lots of different pieces of software such as OSS systems, trouble ticketing systems, billing systems and remote site management software systems to monitor what is happening on site, but these systems don’t talk to each other. Acsys’ solution, while focused on managing physical activity on-site, is to provide an open platform which can integrate with one or all of these third party systems to give a more holistic view of site operations. This fills in the vacuums of data that have existed and presents a complete picture of what is happening at your cell site.

TowerXchange: How long have Acsys been working on this software?

Michael Sothan, Vice President, Americas, Acsys:

It has been very much an ongoing evolving process but something which we have begun to shift our focus more heavily towards in the past year.

TowerXchange: Prior to such a platform being developed by Acsys, how have tower owners been able to monitor operations?

Michael Sothan, Vice President, Americas, Acsys:

What we’ve realised is that whilst the telecom industry is a very high tech industry, when it comes to O&M they have relied on a very piecemeal and low tech approach. Infracos have been amalgamating multiple types and sources of data from digital records to paper based reports right through to word of mouth – all with the aim of increasing visibility and control of their operations. Infracos have been putting in place processes to oversee what is happening but where a lot of inefficiencies have been coming in is that these separate processes are not integrated. There have been a lot of gaps in the data and as such guess work has had to take place. This has made enforcing their processes a real challenge.

Putting in place the Acsys system means that each time a job is being done there is real time data correlated with that job which can then be integrated with further data points. This not only allows for the creation of more effective processes but, perhaps even more importantly, allows for their enforcement.

TowerXchange: How have you worked with clients to develop the solution and what has been their reaction to the system?

Michael Sothan, Vice President, Americas, Acsys:

As we work with clients they give feedback on what data they would like to capture to enable us to create them a tailored system. Generally what most of the clients really want is an increase in the data generated about their O&M and an increase in the efficiency of their O&M. Key questions they’re looking to answer include the obvious; who is on site and what asset are they accessing? This is critical for tenants who want to monitor their active infrastructure, to the less evident; which vendor is doing the job more efficiently? What is the average time spent on site? How many sites can be serviced a day under routine or preventative maintenance?

In terms of the appetite for such a system, we have realised that companies are much more willing to budget for and buy a solution that increases productivity in their operations. Security is an essential component to a towerco business but it is not something that people are excited to purchase. When we can provide a solution that saves people money by reducing their opex, it becomes much more interesting for the client to invest in it.

TowerXchange: Have you developed the solution in partnership with third party software providers? Can most main systems be integrated into Acsys’ solution?

Michael Sothan, Vice President, Americas, Acsys:

With a lot of work still under development, I can’t name all the vendors that we are working with but what I can tell you is that we are working with a number of major remote monitoring system providers from across the U.S., Europe and Asia. With several of them we have already completed integrations and a few have already been deployed in the field. We’ve also been working with some of the major ticketing providers and are now beginning to look at specific billing softwares and larger scale ERP platforms.

The idea is to keep our system as open as possible, using open APIs and web services which allow for integration. The challenge is that we cannot simply make a pre-made system, because every client is using a different mix of softwares and vendors. Instead, on a per project basis, we work with each individual client to see where they are finding gaps in data and look to create a customized solution to fill in those gaps.

The strategy is not to create a pre-made system but to be able to discuss on a project by project basis what each client is using and which gaps they are finding, so that we can create something customised.

TowerXchange: What kind of metrics are clients looking to obtain through using Acsys’ system?

Michael Sothan, Vice President, Americas, Acsys:

Clients are interested in a number of factors. The most critical, but possibly the most overlooked, is very simple - a hard verification of if a vendor visited a site. Without this, how does the infraco, or MNO, know that an assigned task was completed? It all links back to SLA adherence – if you can’t verify whether the visit was even made it makes it impossible to enforce the SLA clauses you put in place.

Next would be vendor time to site and time on site. They want to gain a hard verification of how long it takes a given vendor to reach a site, especially in the case of emergency maintenance, and also how long a given supplier or contractor spends on site. Even if the client is not paying on an hourly basis, they need to have a clear picture of this. If you are putting in place service level agreements you need to be able to monitor this in order to be able to enforce the clauses you put in place. Vendors also need to know they are being monitored. This creates a greater sense of accountability which naturally increases quality.

Clients are interested in a number of factors. The most critical, but possibly the most overlooked, is very simple - a hard verification of if a vendor visited a site. Without this, how does the infraco, or MNO, know that an assigned task was completed? It all links back to SLA adherence – if you can’t verify whether the visit was even made it makes it impossible to enforce the SLA clauses you put in place

Another useful feature of this is that you can develop job based KPIs, working out how long it should take, on average, to complete a specified task. This allows you to better plan your routine maintenance and also enables you to budget more accurately, setting aside a set amount of time for a contractor to do a job, and avoiding overtime payments when they go outside of this.

As well as assessing response and service times or vendors you can also use this to benchmark the equipment itself. For example, if you take a diesel genset you can look at the number of call-outs that it needs on an annual basis and compare the MTTR following a fault. This enables you to make more informed decision making when it comes to equipment procurement.

TowerXchange: From deployment of your systems to date, has Acsys started to observe benchmarks for given tasks and is there anything that you can share?

Michael Sothan, Vice President, Americas, Acsys:

We try to be as consultative as possible in working with our clients but the amount of data that we have access to depends on how independent our client wants to be. In some instances they prefer to keep everything in-house whilst in others we work very closely with them in analysing their data. At the moment the amount of information that we can share is dependent on NDAs that are in place, but we are ultimately very happy to help the client analyse and interpret the data they obtain.

We have however started to see certain trends in different regions. For example, in India we’ve noticed that because of traffic, especially when it rains, there was a certain client which couldn’t get more than one site serviced per day as they were driving back and forth to collect keys. This problem could be rectified by installing our mechatronic locks, taking the number of sites that could be serviced up to as many as four! As such, this also gives us an indication of the number of sites that a client should be able to have serviced in a day.

Another example I can give is in Africa where we did a study on three different vendors carrying out oil filter changes. One vendor was taking 20 minutes to do the change, a second took an hour and a third took two hours. When the client inspected the sites it became clear that the vendor that was doing the job in twenty minutes was frequently not changing the filter at all, whereas the vendor taking one hour was doing a good job. From this we could elucidate that the required time to do an oil filter change was one hour, much less and the job wasn’t being done properly and any longer and the vendor should be more efficient.

TowerXchange: How much analysis is required to extrapolate meaningful findings from the data? Is there a degree of automation?

Michael Sothan, Vice President, Americas, Acsys:

There are certain elements which can be automated, for example with our system you can pre-set alarms if, for example, people are on site too long or are requesting access outside of their normal zone. The system can go as far as automatically blocking access until the vendor’s geo-location is at the correct site. For certain clients we have even built custom reports and automated alarms based off of what they find critical.

If you want to break down findings and connect them to other data points, some of this is still being done manually. Importantly, all of our different reports can be automatically exported in an Excel-ready format, which means clients can utilize all of Excel’s built-in analysis tools to also analyze our data.

Acsys can offer a service whereby our engineers run analysis every week and send a report back to the client and we are always working to add in more ways to further automate the process.

TowerXchange: Why is it so important to improve the way in which infracos can better understand workforce patterns on cell sites?

Michael Sothan, Vice President, Americas, Acsys:

From a very general perspective if you look at the advent of management science you have all these innovative concepts that were developed like systems theory, value based management and lean manufacturing which have been adopted by various industries and are being taught in the world’s top management schools. The approach to managing operations in telecoms infrastructure shouldn’t be any different.

We are trying to equip infracos with the skills to adopt lean O&M in the same way you hear about lean manufacturing – working to achieve more with less, reducing costs and acting more efficiently. Companies that can use tools like ours to identify patterns in workforce behaviour can than weed out the inefficiencies, create optimised processes and obtain a competitive advantage, resulting in them becoming leaders in their field.

A more specific answer to the question is that understanding workforce patterns enables you to better manage staff and subcontractors on site, not only verifying that work is being done in timely and accurate fashion but also enabling you to better plan and forecast work that needs to be done. When you have an indication of how long a job should take you can put in place job based KPIs – planning the amount of time and cost required for a given job, avoiding overtime payments. Similarly by having a definitive answer on whether a job is being done you can enforce SLA clauses, with a data trail in place vendors know that their activities are being monitored. Knowing this means vendors are now required to follow processes established by management which they may have previously ignored.

TowerXchange: Do any other companies have a similar offering to Acsys?

Michael Sothan, Vice President, Americas, Acsys:

There are companies offering wired or Wi-Fi dependent solutions which require a lot of hardware to be installed on site. These companies are generating a lot of data which has the potential to be integrated but the issue is they don’t have the reach to be able to install it on the majority of sites. A high level of expense and time is required to install these systems and as such, the solutions are usually only being installed on a few critical backbone sites. Such systems lose much of their value as they can’t correlate what is happening on those handful of sites with what is happening on the other 90% of the network. No other vendors have the ability to not only install a solution on every single site – from critical backbone sites, to rooftop sites to remote sites out in the middle of nowhere – but also on every asset on the site.

When it comes to other mechatronic lock providers, we don’t see any other companies going the extra mile to utilise or exploit the data that is being generated by the system. They focus exclusively on the security aspect but to us that is just the foundation. Pulling out as much data as possible and making that data work for you!