Sometimes it seems like members of the TowerXchange community are engaged in a war on diesel. Reliance on diesel makes energy opex unstable, it opens up risk of pilferage, spillage, and it tends to result in hefty maintenance bills and a substantial carbon footprint. In what use cases could hydrogen be a compelling alternate fuel? Is LPG ready for use at emerging market cell sites? To learn more, TowerXchange spoke to fuel cell technology veterans ReliOn.

TowerXchange: Please introduce ReliOn – where does your company fit in the telecoms infrastructure ecosystem?

Joe Blanchard, General Manager, Stationary Power, ReliOn:

ReliOn has been delivering hydrogen fuel cell products to the telecommunications industry since 2003. We have significant experience on our management team in telecom with several industry veterans of over 25 years.

ReliOn was recently acquired by Plug Power, Inc., a publicly-traded fuel cell company whose products are used by a number of Fortune 500 companies in material handling applications for their warehouses. ReliOn continues to serve the stationary fuel cell market, including its largest market, telecommunications.

The proton exchange membrane (PEM) technology we use is the mainstay for fuel cell applications in telecommunications. While ReliOn don’t provide PEM technology for cars and buses, the fact that it is also the primary fuel cell solution for automotive has positive implications from a volume and cost point of view.

ReliOn has shipped fuel cells to more than 1,900 customer locations in 36 countries. We count among our customers several tier one telecommunication companies: AT&T, Sprint, Verizon, and Hutchison (Indonesia) as well as numerous smaller carriers. We serve applications ranging from various sizes and types of base stations, point-to-point microwave sites, as well as push to talk LMR sites. Though commercial telecom is our largest customer base, we also provide solutions to customers in the railroad, utility telecom, government communications and security sectors.

TowerXchange: The first question our readers always want answered is “how proven is the solution in emerging markets?” Tell us about some of your deployments to date.

Joe Blanchard, General Manager, Stationary Power, ReliOn:

Most of ReliOn’s installed footprint is in North America and Europe; however, we have had some traction in emerging markets.

In Southeast Asia our solutions are in use on 200 Hutchison sites through our partner, Consistel, plus 20 sites in Thailand. We are engaged in other trials throughout Southeast Asia and China, plus have completed extended market trials in India. In some of these countries, we have localised production of certain product components. This both provides a lower total cost to the customer than shipping overseas and supports the local economies.

With Open Mobile, ReliOn fuel cells are in use at 15 rooftops in Puerto Rico, with a further 30+ sites throughout the Caribbean.

The issue in emerging markets often comes down to the feasibility of the selected fuel. ReliOn has, to this point, been mainly focused on hydrogen-fueled product. In many cases, hydrogen is the best option for a few different reasons:

It offers the simplest technology: connecting a hydrogen cylinder to the fuel cell via piping provides very little opportunity for malfunction or breakdown.

It offers the lowest emissions, though methanol fuel processors have much lower emissions than diesel generators, they still do emit some pollutants.

Much less standby energy is required compared with a fuel processor which needs to be kept at a temperature to be ready to quickly produce hydrogen when called upon.

Recently, our focus has widened to include alternative fueling options in order to better serve our customers in some emerging markets where a hydrogen model is not feasible.

In early 2014, ReliOn and Acta signed an agreement whereby both companies promote two Acta products that integrate the Acta electrolyzer with ReliOn’s fuel cells: the Acta Power HT (2,500W and 5,000W) and Acta Power Cube (200W – 1,100W). These products open markets in emerging countries where fuel of any kind is logistically difficult. Acta promotes the products outside the U.S.

Additionally, ReliOn has been developing a methanol fuel processor and currently has implemented initial customer trials in North America. Understandably, it is easier to work through early product installations closer to home. ReliOn anticipates introducing a commercial product more widely in 2015.

Because ReliOn’s products were developed to meet requirements in the North American telecom market, we’ve complied with rigorous quality standards. So the performance of our fuel cells, their energy conversion efficiency, and environmental footprint are all outstanding. Our units perform autonomously in temperatures from -40°C to +50°C, and from sea level to 15,000ft. This means the inherent design of ReliOn’s solutions makes them resilient to extreme conditions in emerging markets, from monsoons to deserts.

TowerXchange: Why are fuel cells particularly suited to powering rooftops?

Joe Blanchard, General Manager, Stationary Power, ReliOn:

Many rooftop owners and permitting authorities do not allow liquid fuels on rooftops, which makes siting generators difficult or impossible. Because hydrogen is lighter than air, it does not pose the environmental and safety issues a liquid fuel poses and can be much easier to permit.

As many rooftops represent comparatively low energy loads, fuel cells can provide significant runtime, whilst overcoming the challenges caused by the architectural integrity of buildings leading to strict weight limits, which also make the installation of batteries for more than 4-8 hours problematic. Our solutions are in use at 40-50 sites across the Caribbean and LatAm, particularly in urban areas with unreliable grids. Fuel cells are a good fit for these fill-in base stations.

TowerXchange: Do ReliOn sell direct or via channel partners?

Joe Blanchard, General Manager, Stationary Power, ReliOn:

While we sell direct in the U.S., we use channel partnerships worldwide, with representation in Southeast Asia, South Africa and India. We train and enable local partners, and we won’t go around them and sell direct once relationships are established.

We think native language and time of day support is critical, and that local methods and procedures are understood.

We also work with several OEMs – we have either formal or informal relationships with Huawei, Ericsson, Nokia and Alcatel-Lucent, as well as working with the major power system providers like Delta, Alpha and Emerson, enabling them to have detailed knowledge of our products to coach the customer to engage with us if fuel cells make sense in a given context.

TowerXchange: When discussing fuel cells as a power solution for remote cell sites, one concern expressed has been that replacing a diesel logistics model with a hydrogen logistics model does not significantly reduce cost and complexity – how do you address such concerns?

Joe Blanchard, General Manager, Stationary Power, ReliOn:

Replacing a diesel logistics model with a hydrogen logistics model is essentially a swap out, rather than an upgrade. However, replacing diesel fuel with hydrogen fuel offers many benefits:

Pilferage: Hydrogen and other alternate fuels have much less chance of being a target of theft.

Spill abatement: Hydrogen is lighter than air and dissipates when leaked, whereas diesel saturates the ground when spilled or even enters lakes and streams. Diesel spills lead to costly cleanup procedures and fines.

Availability during storms: During a weather event like 2012 U.S. Hurricane Sandy, diesel can be in short supply and may be diverted to “more critical” needs. Currently, hydrogen is less frequently used and may be in greater supply during a crisis event.

Emissions: Hydrogen has no emissions at the point of use – diesel used in an internal combustion engine emits particulate matter, carbon monoxide, nitrogen oxide and carbon dioxide. Even at strict Tier 4 levels, these emissions lead to an increase in smog, hazardous air quality and greenhouse gases.

We recognise that whether you’re in rural Zimbabwe or the most populous location, fuel logistics are a common challenge. We can help establish an operational Service Level Agreement with your own staff or with a third party fuelling company to support them in normal operations or in providing coverage during storms. We can take the same team that handles diesel and train them how to deliver hydrogen.

We have also been using methanol-water reformers, which produces hydrogen from a higher energy-density fuel, thus reducing site visits for refueling.

TowerXchange: Is LPG a compelling alternative fuel resource for off-grid cell sites?

Joe Blanchard, General Manager, Stationary Power, ReliOn:

Because of ReliOn’s acquisition by Plug Power, we now have had access to significant LPG and natural gas based solutions. If refueling logistics are comparable whether you use diesel, hydrogen or LPG, and availability of fuel is not ubiquitous worldwide, then the optimum selection of fuel depends on the availability and cost in a given location. For example, there are areas where everyone can get LPG yet diesel is tough to come by. Telecoms energy solutions must fit into different models depending on customer need.

We think there may be pent up, untapped demand for LPG based solutions.

However, we don’t think LPG solutions are ready for commercial deployment in telecommunications power this year, but we’re looking at them for the future.

Additionally, some companies are working on fuel processors that use Ammonia (NH3) as a fuel source. Ammonia is widely used in agriculture throughout the world, so it is another option as a source of hydrogen.

TowerXchange: How do fuel cells compare with more widely used diesel generators as backup power solutions, in terms of complexity and therefore reliability?

Joe Blanchard, General Manager, Stationary Power, ReliOn:

Diesel generators have many moving parts. It is a stretch to claim diesel generators consistently reach about 70% reliability; we have seen start-up data (which may not be the generator’s fault) in the high 20% range. In order to keep diesel generators functioning properly, so that they are ready for use in an outage event, monthly or quarterly maintenance of multiple components is suggested.

Ultimately there are different classes of DG equipment – we’ve seen some very robust DGs and others that barely last 500 hours in a remote cell site context! Much depends on the manufacturer and the technology that you’re using, for example using a 3,600rpm or an 1,800rpm model changes life expectancy dramatically.

Third party verified reliability of hydrogen fuel cells reaches up in the high 90s – from 96 to 99.7% depending on the manufacturer

Hydrogen fuel cells have very few moving parts; just fans that circulate air. The maintenance requirement for a fuel cell is an annual inspection of air filters and possible cleaning or replacement of the filters if needed. Third party verified reliability of hydrogen fuel cells reaches up in the high 90s – from 96 to 99.7% depending on the manufacturer.

TowerXchange: How can the performance and longevity of fuel cells be optimised?

Joe Blanchard, General Manager, Stationary Power, ReliOn:

In markets like India, air filtration is critical for the longevity of fuel cells. Dusty air will degrade performance; we have sites that have not needed filter changes for 3-4 years, others that might perform optimally with a filter change every six months, so replacement regimes for filters are highly dependent on climate and air quality.

Like a DG, a fuel cell still needs a small amount of energy to startup, so using robust energy storage solutions optimises reliability. I believe fuel cells augment the use of good batteries on remote cell sites – ideally one should use batteries during short outages, with fuel cells operating during the longer outages that would otherwise be particularly harmful to availability and the Customer Experience. Operators that have used fuel cells have shown significant improvements in reliability and uptime, especially where there are long periods of time between usage of backup power systems.

TowerXchange: Are buyers of fuel cells eligible for tax exemptions and carbon credits?

Joe Blanchard, General Manager, Stationary Power, ReliOn:

One carbon credit is awarded for every ton of CO2 either removed, avoided or sequestered (via carbon trade exchange).

Carbon credits can be generated from various types of projects including:

Renewable energy: a switch from fossil fuels to a ‘clean’ energy e.g. wind and solar energy.

Forestation and afforestation: the planting of new trees as trees sequester and store CO2 e.g. forest regeneration.

Energy efficiency: reducing emissions though an increase in energy efficiency e.g. installation of energy-efficient machinery.

Methane capture: avoiding methane emissions through capture and burning to create energy e.g. landfill methane capture.

Project eligibility for carbon credits depends on whether a project follows one of the Kyoto Protocol’s project-based mechanisms or an independent voluntary standard.

While there do not appear to be current fuel cell projects in telecom that are receiving carbon credits, it does appear they are able to do so, if a company were to take the time to develop a project through one of the carbon credit registries.

Tax exemptions outside the U.S. come under a variety of programmes and names. Admittedly, it is more difficult to find applicable programmes in developing nations.

TowerXchange: Talk to us about the modularity and scalability of fuel cell solutions as additional tenants and additional load is added to cell sites?

Joe Blanchard, General Manager, Stationary Power, ReliOn:

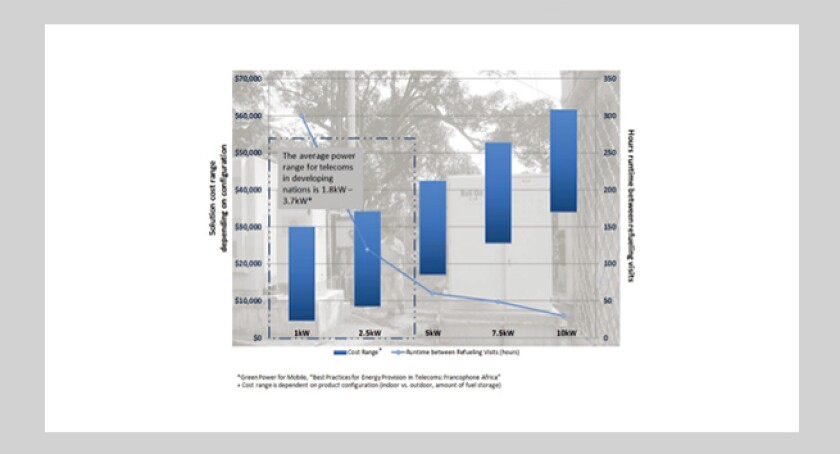

ReliOn fuel cells are designed to be modular and scalable. We encourage customers to buy what they need in terms of power, knowing that they can add more power in the future if their needs change. ReliOn offers several products that we use as building blocks to meet a customer’s power requirements. We can cover microwave applications needing 75W as well as multi-tenant cell sites reaching up to 20kW and everything in between. Our fueling solutions are also modular and scalable, so that we can meet the runtime needs of our customers.

ReliOn fuel cells are designed to be modular and scalable. We encourage customers to buy what they need in terms of power, knowing that they can add more power in the future if their needs change

Modular design principles minimise the initial capital cost for the customer while leaving room for future upgrades.

Another key advantage of fuel cells is that because they provide DC power, fuel cells can be used as backup power for other DC components including rectifiers. Also, with a DC power solution, there is no need for a transfer switch, as would be required with an AC solution like a diesel generator.

TowerXchange: Finally, please sum up what differentiates ReliOn from other fuel cell solution providers.

Joe Blanchard, General Manager, Stationary Power, ReliOn:

It’s really the combination of three things:

Innovation: ReliOn’s continuous innovation in core fuel cell technology has made us a leader in the development and marketing of modular, scalable fuel cell products for customers seeking solutions to critical backup and grid-support power applications. Many fuel cell companies are more like integrators, using core technology purchased from other fuel cell developers and wrapping electronics and sheet metal around it. ReliOn uses our own technology, and are organised into focused industry verticals bringing our product to market – we use our own ideas, own product, own R&D and a combination of outsourced, localised and in-house manufacturing.

Collaboration: Just like our customers, we want to get it right the first time, every time. Their input and our experience together guide us to the optimal solution for each application. We’ve worked with our customers from the telecom space and other markets to fit our products to their needs… not the other way around. When they offer feedback, we listen and then use their comments to improve our next product iterations.

Results: 5.7MW of fuel cell power sold & shipped. 1,900+ customer locations in 46 U.S. States and 36 countries. ReliOn is the leading supplier of fuel cell products to the top three telecom carriers in the U.S.