TowerXchange caught up with Tom Tipple, one of the evangelists of vanadium redox energy storage technology, as he settled into a new role as Regional VP for Europe, Africa and the Middle East at Imergy Power Systems. Vanadium redox batteries are known to be a good fit for emerging market telecoms, in that they have a ten+ year lifespan and can partially charge or discharge an unlimited number of times according to the availability of grid or renewable power sources without any degradation in performance. However, the capital cost of vanadium redox technology has been prohibitively expensive for many applications… until now!

TowerXchange: Please introduce Imergy Power Systems and your role in the telecoms infrastructure ecosystem.

Tom Tipple, Regional Vice President, Imergy Power Systems:

Imergy manufactures a range of vanadium redox energy storage solutions, and has been operational since 2006. Originally operating as Deeya Energy, who built an impressive base of technology and clients in India, we changed our name at the end of 2013, coinciding with the introduction of new investment and a new management team.

Our new management team comes with impressive credentials; Bill Watkins is an award-winning CEO who previously headed up Bridgelux and Seagate Technology, and Tim Hennessy was President of Prudent Energy and CEO of VRB Power Systems Inc. which commercialised the VRB® technology.

Imergy is the first company to take flow battery technology to the next stage – driving down costs while maintaining high quality. Our innovative approach to manufacturing and financing takes us into the specialist area of serious volumes, delivering batteries not in the usual orders of tens, but in orders of thousands of units.

TowerXchange: The first thing our readers usually want to know is “how proven is the solution in the field”, so please tell us about your experiences at cell sites in India, Africa and Indonesia over the last two years.

Tom Tipple, Regional Vice President, Imergy Power Systems:

The predecessor to Imergy, Deeya Energy, focused on the Indian market, where their manufacturing base was located, and where they have over 75 systems installed over five years with virtually no failures. Clients include Airtel and American Tower, and we’re about to sign a 200 system order with a big Indian telecoms operator in the next month. We continue to see significant market demand for our products.

Clients include Airtel and American Tower, and we’re about to sign a 200 system order with a large Indian telecoms operator in the next month. We continue to see significant market demand for our products

With the new investment and new management team, Imergy is now more of an international company, seeking opportunities in Africa, the Middle East and Asia (for example Myanmar and Indonesia) – one of my objectives is to broaden our international horizons.

TowerXchange: What has been the interest in your solutions from Africa?

Tom Tipple, Regional Vice President, Imergy Power Systems:

We’re talking to most of the African towercos and several MNOs, and have three pilots scheduled from June – one in the West, one in the East and another in Southern Africa. We currently have an active trial in Nigeria with our smaller 2.5kW system, which is great for single tenant remote sites, but not ideal for multi-tenant towers. The new ESP5 system addresses that higher power requirement.

TowerXchange: What is the ‘sweet spot’ for the load your systems are able to support? And how are solutions scalable as single tenant towers become multi-tenant sites?

Tom Tipple, Regional Vice President, Imergy Power Systems:

From an applications point of view, we are an ideal storage technology for microgrid, off grid and weak grid solutions, with or without PV installation.

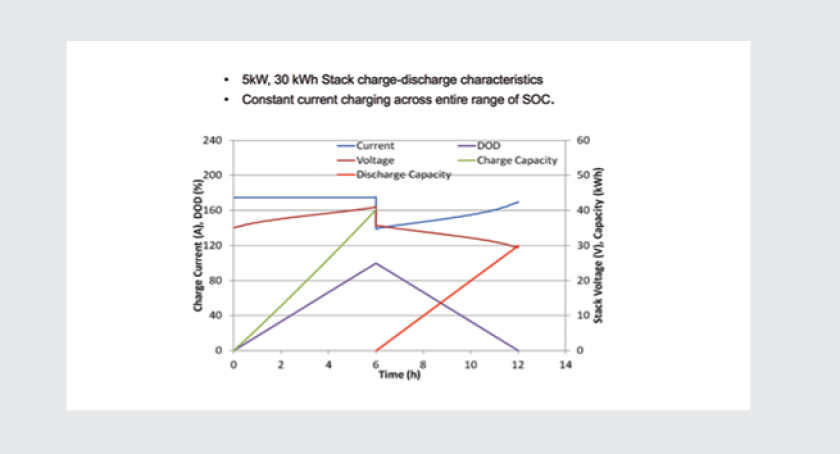

We’ll be introducing our new ESP5 system in August, which is a nominally rated 5kW system (at its most efficient), but able to output at a continuous 7kW. So we can now address small, remote installations with our 2.5kW system, right up to larger multi-tenant sites with our 5kW system. Once you get to loads above 8kW, you simply add a second system. For data centres and other larger installations, we have a 30kW / 120kWh energy storage system available in October and a new 250kW modular solution due in 2015, for large solar farms, grid stabilisation and load shifting.

In terms of modularity and scalability, as long as the customer specifies up front that he requires a modular solution, which means we add an additional slot for an additional stack, it adds a small 5-10% cost to be upgradeable from a 2.5kW to a 5kW stack. We can also increase energy capacity simply by adding more electrolyte.

TowerXchange: For readers unfamiliar with vanadium redox technology, please explain why it is so well suited to energy storage at emerging market cell sites.

Tom Tipple, Regional Vice President, Imergy Power Systems:

The whole idea of using vanadium redox is to maximise energy saving – we capture power from the grid, from diesel generators and from any renewable power sources as quickly as possible through the batteries’ fast charge capability. Our batteries are used in diesel hybrid solutions or as backup power for weak grid sites where outages occur on a daily basis.

But the unique thing about Vanadium Redox batteries is that they can cycle an unlimited number of times, using the full charge capacity, whereas other energy storage technologies such as lead-acid are handicapped by a finite lifecycle, and you need to follow strict guidelines to maximise that lifecycle. You have to make many compromises with lead acid battery solutions to maximise the life expectancy. Physics tells you that lead acid is simply not the right technology for long term cycling or for partially charged requirements. Cheap in the short term, but with poor performance and needing constant replacement.

Vanadium redox batteries will last at least ten years and this life expectancy is totally independent of the number of cycles. With vanadium redox you can stop and start charging and discharging at any state of charge with no effect on the performance or life expectancy of the battery. That’s absolutely critical for sites on weak grids where you don’t know when the power will come back on.

TowerXchange: The warranties on the batteries used on cell sites are notoriously difficult to claim against – what’s unique about Imergy’s solution in that respect?

Tom Tipple, Regional Vice President, Imergy Power Systems:

We offer a five year warranty as standard; we don’t have any warranty limitations on temperature, number of cycles and depth of discharge, and we’ll sell an extended ten year warrantee at very low additional cost.

In comparison, lead acid battery warranties have guidelines covering temperature, depth of discharge and charge profile management. In order to claim a replacement battery under warranty, you need comprehensive records to prove you kept to the manufacturers recommended guidelines, and no-one really has that depth of record keeping. Very few companies have managed to get their money back or replacements covered under the warranty on a lead acid battery; it’s elusive.

TowerXchange: What’s the timeline to ROI in Imergy’s vanadium redox batteries?

Tom Tipple, Regional Vice President, Imergy Power Systems:

Due to the straight line / fast charge capability, the ESP5 can deliver a much higher run time saving than other battery technologies, so we offer better opex savings on fuel. On a typical off grid site, the ROI is well under two years. The TCO figures over three years and beyond are better than other storage technologies as there is no replacement cost. For most equipment buyers, achieving an ROI under over three years is critical, while ESCOs looking at seven years power provision contracts find the vanadium redox system a very compelling proposition.

TowerXchange: What is unique about Imergy Power Systems ESP installations’ chemistry and manufacturing process?

Tom Tipple, Regional Vice President, Imergy Power Systems:

Thanks to the unique chemistry of the electrolyte, our vanadium redox batteries have a high temperature rating – up to 50 degrees, which means in most locations you don’t have to worry about cooling. Other competitive energy storage solutions have much lower temperature restrictions, meaning they need some sort of cooling, which adds a parasitic load.

The cell stack is the brain of the system; it converts electrochemical energy into electricity. With most flow batteries, the membrane component of the cell stack has been inherently expensive to produce. However, Imergy have a unique cell stack design that reduces our manufacturing cost enormously while maintaining efficiency.

We have also outsourced manufacturing to Flextronics who are a highly reputable contract manufacturer. They bring volume production capability at low cost without compromising on quality.

TowerXchange: Even if your energy storage solutions can deliver twice the opex savings compared with lead-acid batteries, how do you overcome the difference in initial capital outlay?

Tom Tipple, Regional Vice President, Imergy Power Systems:

Up to now the business case for vanadium redox has always suffered because of a higher up front capital cost compared to lead-acid; however the new ESP5 offers energy capacity at just over $700 / kWh which represents a real price breakthrough for small systems. This is a complete system price including a built in generator controller, remote monitoring system and housing – not just the battery part.

We are also able to offer a split capex-opex financing model which reduces the upfront capital outlay. We lease the electrolyte separately from the capex items such as cell stacks, housing controllers and electronics. By retaining ownership of the electrolyte, and leasing it over a five year period, we can bring down the capex element by 50% making it comparable to a lead-acid solution. This model is particularly attractive to the growing numbers of ESCOs as they can afford to take advantage of advanced storage solutions, generating better savings with much more of a levelised cash outlay.

By retaining ownership of the electrolyte, and leasing it over a five year period, we can bring down upfront capex by 50%

How can we do this? The electrolyte simply does not change over time – it has retained, re-usable value. We’re happy to take the electrolyte back if the customer ever moves to a new energy storage system. All the other energy storage systems are entirely disposable – a large proportion of our system is entirely re-usable.

TowerXchange: What does it cost?

Tom Tipple, Regional Vice President, Imergy Power Systems:

The outright capital purchase price for a 5kW / 30kWh system (equivalent to a 48VDC 1,200 Ah lead acid battery solution operating at 50% DoD) is around US$22,000 in volume, and includes a five year warranty.

Ordering the same system under our split capex-opex model reduces the upfront capex to around US$11,000, equivalent to a good quality lead acid system. Over a two year period, the monthly lease for the electrolyte works out at around half the cost of replacing the lead acid batteries. At the end of the five year lease, if a new energy storage innovation becomes available, we take back the electrolyte – all the customer has to do is deliver it to a port of convenience to collect. Or he can opt for an extended five year warranty at minimal cost.

We have designed the system to be a simple replacement into most existing sites. The ESP5 includes its own battery hybrid controller to manage the generator run time according to the charge capacity – plus a remote monitoring system measuring performance that can either be independent or ported to a third party RMS. The only additional equipment you need a charging device onsite, and we can usually work with existing equipment on site. The cost of a complete ESP5 system with its enhanced OPEX saving performance now makes Vanadium Redox flow battery technology a very attractive proposition.