TowerXchange was once asked whether the integration of M2M-enabled sensors into cell site equipment would eventually render existing RMS systems redundant? We think the opposite - the integration of varying communication protocols from different sensors and the communication of the information back to the NOC has never been more important. HMS Industrial Networks’ Netbiter solution enables tower owners to connect any equipment with a communication interface to their gateway, which in turn provides critical information which the NOC can use to reduce opex costs. By understanding when, how and if equipment is operating, tower operators are able to make better decisions regarding site maintenance and take actions when necessary.

TowerXchange: Please introduce TowerXchange’s readers to HMS Industrial Networks, particularly your experience in telecoms

Bartek S Candell, Global Key Account Manager, Telecom Infrastructure and Energy, HMS Industrial Networks AB:

HMS is a leading supplier of industrial communication technology with 350 employees, operations in 10 countries, and distributors in over 50 countries. We’re a public company with annual turnover of €50m+. While the company was founded in 1988 and our initial applications were in industrial automation and control, we got into the telecom business three years ago; having supplied RMS to diesel generator control panel manufacturers for many years, we realised we could expand the package to provide more holistic monitoring and management of important aspects such as energy generation and consumption, and package it in to a ‘plug n play’ solution.

We have two brands of interest to TowerXchange readers: Netbiter Remote management Solution (RMS) and Anybus protocol converters for industrial communication.

Every device, whether on a cell site or production floor, has its own communication protocol, and the amount of protocols is increasing dramatically. HMS’s Anybus embedded communication modules enable communication in-between devices and networks. The Netbiter gateways and Netbiter cloud services connect devices and enable remote monitoring, management and control. This provides instant access to information such as system status, performance and provides possibilities to analyse and remotely operate equipment. In turn this enables operators to reduce cost and improve efficiency, better analyse equipment behavior, and to transform maintenance procedures from reactive to proactive.

Cell sites are often serviced according to pre-determined, scheduled maintenance. As site visits, particularly to remote sites, are costly, those costs can be reduced through RMS by monitoring and configuring the site remotely. The benefit is that you will be able to send teams only to sites that need servicing, and you will also know in advance what equipment to tend to, enabling a team with the right skills to be dispatched.

TowerXchange: Tell us about the installation of your system and how it’s connected back to the NOC.

Bartek S Candell, HMS Industrial Networks AB:

It requires minimum of technical expertise to install the Netbiter gateway at a cell site. It’s plug and play - all you have to do is install the hardware to the rack, power it up, connect to the equipment you wish to monitor and/or control, and leave the site - the gateway connects automatically with our Netbiter Argos cloud service. With all configurations undertaken remotely via the cloud, tower operators avoid the need to employ high cost, scarce engineering skills to install our system.

Remote connectivity is provided via 3G, GPRS or Ethernet. We offer our own web-based front end, often used for more advanced configuration of existing equipment on site. Many customers use our API to integrate Netbiter cloud service with their third party OSS software, gathering data directly from our cloud into their own system.

TowerXchange: What equipment can Netbiter monitor at a cell site?

Bartek S Candell, HMS Industrial Networks AB:

With the minimum of site modification, we can monitor and control basically any existing equipment on a site through our M2M communication interface.

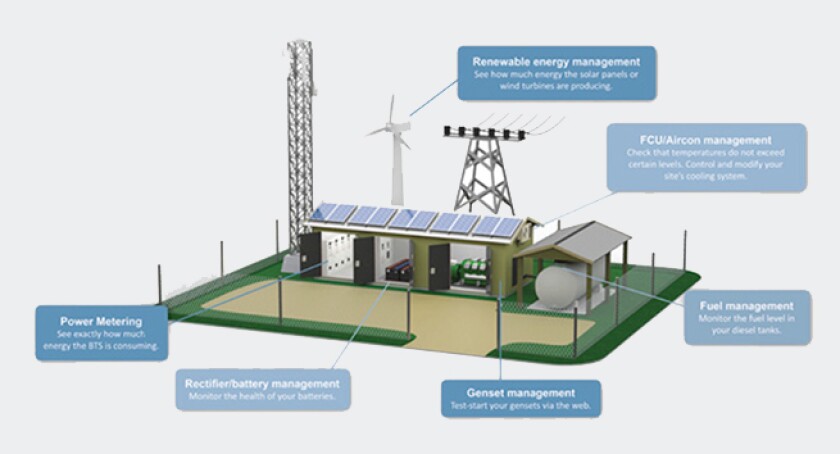

Netbiter is available in building blocks - it’s like a menu from which you can select ingredients such as:

Fuel management

AC metering

DC metering

Genset management

Rectifier and battery management

Renewable energy management

Fuel cell management

Free cooling / air conditioning management

TowerXchange: How big is the fuel theft problem at cell sites, and how do you help tower operators overcome that problem?

Bartek S Candell, HMS Industrial Networks AB:

The Indian telecom industry consumed 3200bn liters of diesel during 2012 and the estimation is 4400bn litres of diesel in 2014[i]. Customers have told us that approximately 30% of this can be fraud! This is of course a huge problem and we decided to come up with a good solution for this. But since our core business is remote communication and we had to come up with a high quality solution for level measurement, our choice was to team up with a German world leading manufacture of level measurement sensors - Pepper & Fuchs.

The outcome of this great partnership is a very unique, top mounted ultrasonic sensor able to measure tank level, refilling, consumption and theft. To reach high resolution and accuracy we needed to take the environmental aspects into account. The sensor is compensating for temperature changes in the diesel tank as well as humidity. If a tank is mounted underneath a generator we compensate for the vibrations from the genset as well. With this high accuracy data collected we can easily present correct tank level, theft (on customer defined thresholds), low/high level alarms and most important; verify the refills and reduce the fuel refill intervals.

The ultrasonic sensor is tamper proof - if someone cuts the cable or removes the sensor we immediately get an alarm that incoming data is not correct.

Furthermore, what’s unique about our ultrasonic sensor compared to other sensors is the possibility of remote configuration. Basically the only thing you do on site is to mount the sensor on a tank and connect to the Netbiter gateway. The rest is done remotely.

TowerXchange: Tell us about your system’s capabilities in genset management.

Bartek S Candell, HMS Industrial Networks AB:

We have for several years been the preferred RMS supplier to many of the world’s leading genset control manufactures. If you connect the Netbiter gateway to the genset controller via existing Modbus interface you get access to all the parameters and settings you would have locally on the controller like DG runtime, genset output, battery levels, oil pressure, engine RPM, coolant temperatures et cetera. Our solution then enables you to remotely set parameters, or start / stop the genset and collect alarms. If there is no Modbus available you can easily connect the dry contacts to the Netbiter gateway’s built-in I/O ports.

In Europe the problem is actually opposite from other markets, the DG’s are not running that often. Our customers use our solution to remotely test-run the DG’s to verify their operating status so they are ready to start when really needed.

But probably the most important factor is that our RMS solution enables the tower operator to switch from scheduled to predictive maintenance of the DGs, creating savings in all the aspects that relates to service trips.

TowerXchange: How does Netbiter measure and enable the better management of the performance of cell site energy?

Bartek S Candell, HMS Industrial Networks AB:

Netbiter enables tower operators to monitor the availability, quality and consumption of all incoming power, existing (passive) equipment and the telecom load. It’s possible to connect up to 32 energy meters to our gateway, this can be already existing meters or meters supplied by HMS. The solution makes it simple to keep track of multi-tenant sites but most import; by measuring the incoming power and consumed telecom power you easily get a site energy efficiency ratio to compare with other sites which by evaluating the result, allows you to target underperforming sites that require investment.

All data is collected in the Netbiter RMS cloud and can easily be extracted in weekly and monthly reports, exported to excel format, or sent via the API to customers’ existing SSO.

In a similar way, Netbiter enables the management of free cooling, air conditioning units and PIU’s (i.e any equipment with Modbus) - with full remote access. We can collect all parameters, change settings to manage alarms and monitor when to change filters or perform any other necessary maintenance related activity.

Finally, I also want to mention that in Q4 of this year we’ll be releasing a new product which enables a transparent channel to ex Energy controllers or rectifiers enabling upload of new firmware or the downloading of log files from the rectifiers. This will further strengthen our offer and allow us to expand our capabilities in site monitoring!

TowerXchange: What’s HMS’s installed base in Africa?

Bartek S Candell, HMS Industrial Networks AB:

As Africa is a new market for us our presence is not that big.

In Angola we are rolling out our solution on 1,000 cells where the customer will monitor and control the DGs remotely.

I can also tell you that we are working with one of the world leading technology suppliers for cell sites.

HMS will be going an African Roadshow with Business Sweden, Ericsson and other Swedish telecom suppliers this year. We will also attend the Towerxchange Meetup Africa, and we are as well working on several tenders from the region.

TowerXchange: Please give our readers an idea of the capital outlay required on a per site basis and the timeline to RoI.

Bartek S Candell, HMS Industrial Networks AB:

Of course the answer varies according to which equipment is being monitored on a site, the level of existing diesel theft/fraud and the cost of diesel in the local market. Assuming that we have a cell site with DG running 24/7 with a consumption of 2 liters/hour (0,80EUR/liter diesel) and 4 % fraud, will give us an RoI of 12 months.

The Netbiter Remote management solution for one site starts from approximately EUR360 for the hardware and approximately EUR50 per year for cloud services.

[i] http://www.greenpeace.org/india/Global/india/report/Enabling-Clean-Talking.pdf