Galooli are in the opex saving business. Whether they’re saving fuel, maintenance or overhead costs, their objective is to help asset owners reduce the impact of opex on the bottom line. Galooli position themselves as a holistic provider of remote performance monitoring software and hardware, enabling preventative rather than reactive maintenance, and they believe post-sales service is a critical differentiator. TowerXchange spoke to Galooli’s Ronen Barel to find out more.

TowerXchange: Thanks for speaking to us today Ronen. Where do Galooli fit into the telecoms infrastructure ecosystem?

Ronen Barel, CEO, Galooli:

Galooli develops and manufactures software and hardware for the performance monitoring of remote assets. While one of our strongest segments is telecom monitoring and analysis, we also offer fleet management and tracking, energy metering and monitoring for construction groups.

Concentrating on our telecom services, I see three major differentiators from our competitors. First, Galooli provides a holistic solution. We don’t just monitor sites, we also monitor the fuel tankers, company vehicles, compounds and the technicians themselves - all on the same platform.

Second, we enable preventative instead of reactive maintenance. Whether you’re faced by an instance of fuel theft or a piece of equipment malfunctions, if it’s an eight hour journey to that site, you are likely to suffer downtime, which can mean losing ground to a competitor. Thanks to our analysis of the performance of all assets, we provide tools that make it easier to make good preventative maintenance decisions that prevent such incidents from happening.

Our third differentiator is that we believe in service, not just in technology. We have the best system available in the market, but we believe in post-sales service. We’ll never make an offer in a territory where we don’t have our own local people on the ground to service the system and analyse data - in some instances those people will sit in customer premises.

Any remote performance monitoring system without post-sales service will die after one year because no one will use it.

TowerXchange: What is Galooli’s deployed footprint in emerging markets, particularly Africa? Are you working with towercos as well as MNOs?

Ronen Barel, CEO, Galooli:

Galooli are headquartered in Israel, with local offices in Uganda, Nigeria and South Africa (with an office opening soon in Brazil). We also have distributers in a further 22 countries.

Yes, we work with towercos as well as MNOs - when a towerco acquires sites from one of our operator clients, we become a supplier to the towerco. I think the towerco business model will continue to penetrate more and more into Africa.

There are three reasons that tower management companies are working with us. Firstly, tower monitoring in real time is not that complicated, but full monitoring coverage of the fuel cycle is critical in Africa. Fuel security is the number one problem in many countries. Because Galooli came from a fuel monitoring background in mobile assets - our first telecom project was fuel site management, not even cell sites - we are specialists at fuel monitoring. We are able to offer real visibility of fuel theft and management of the fuel cycle from the fuel station to the tankers to the cell site. A lot of fuel theft originates in the fuel station or takes place between the station and the cell site, so if you concentrate on monitoring fuel tanks at cell sites, you’re only addressing part of the problem.

The second reason the towercos trust us is because of our reliability - our people and our service. Galooli provides reliable data, and we do what we say we’re going to do.

Our third benefit for towercos is that if you have more than one tenant on a tower, our energy metering for each tenant means the towerco can bill the tenant according to their energy usage from the grid and from the generator.

TowerXchange: Please tell us how tower operators can achieve RoI in site management systems such as yours?

Ronen Barel, CEO, Galooli:

The main RoI is achieved by simply making the right decisions based on information coming from the system - such as enabling the shift from reactive to preventative maintenance which I mentioned earlier.

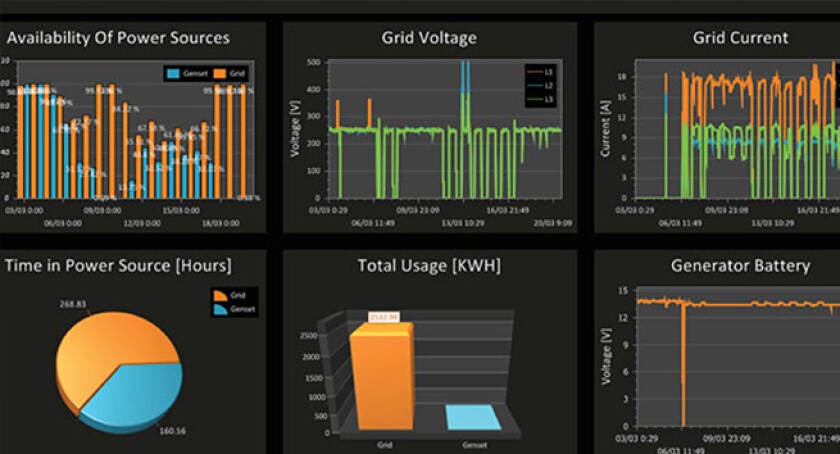

If you’re not monitoring your fuel cycle and your cell sites based on true data you can trust, then you’re blind to everything related to site until someone physically visits that remote site to conduct a survey. The reality is that some cell sites in Africa are in such a bad condition that QoS and uptime are seriously affected. We’ve seen sites where the generator has been partially dismantled, there are no functioning batteries, and the rectifier is virtually empty. Such sites only work occasionally when the grid is online. Once you monitor your sites, you have information on batteries, rectifiers, genset runtime, fuel quality - loads of data! Without RMS, you’re totally blind.

TowerXchange: How do monitoring systems enable preventative maintenance, and what are the change management implications?

Ronen Barel, CEO, Galooli:

Let’s talk about fuel for example. If your contractor refuels sites on your behalf, you’re exposed to the risk of fraud within the station, theft on the way to the site, and from the site itself. With remote monitoring, you can pay only for fuel consumed by the genset, immediately switching responsibility and liability for fuel theft to another entity, who may in turn subcontract that responsibility to a security company. You can create a process that forces contractors to work according to your rules.

Our integration of RMS and access control enables tower operators to better monitor the maintenance procedure on sites. You can enforce maintenance SLAs because you know where the field maintenance engineers are, and you know what they are doing. Again, it’s all about enabling simple decisions based on simple data.

I don’t think tower operators can afford to give up on even one site. There is no choice but to fight back against fuel theft

TowerXchange: How do you counteract the risk of people within the supply chain tampering with sensors if they want to conduct fraudulent activity?

Ronen Barel, CEO, Galooli:

If you use RMS to combat fuel theft, tampering will inevitably occur. It’s not just by maintenance staff, it’s by everyone who has interests. Our system sends the NOC tampering notifications, and enables tower operators to know who logged into the site when tampering occurred. So you know who to call and where to start your investigation.

We also work on prevention, using mechanical systems to protect fuel and assets, and using metal covers for batteries and fuel tanks - equipment that makes it more intimidating for people to tamper with the sensors.

I don’t think tower operators can afford to give up on even one site. There is no choice but to fight back against fuel theft.

TowerXchange: Tell us about the integration of Galooli’s systems and data with the NOC.

Ronen Barel, CEO, Galooli:

We provide a full solution at the NOC, a push system that integrates with OSS solutions and servers. We provide alerts of any incidents or metrics of concern, prioritised based on severity, that can be communicated by mobile, SMS or email. Each alert can be escalated according to certain parameters. For example, if a sensor tells us a door is open but a field technician is on site, no problem. But if that door is still open six hours later, we have a problem.

There are different parameters for different assets, for example we would escalate within five minutes if a tower light weren’t functioning.

Our second layer of users are operational people, finance and network managers - even top management who sometimes only want a snapshot of assets or of how much money was lost to fuel theft in the last 30 days. We also provide various ad hoc reports and deeper analyses, supporting a whole range of staff.

TowerXchange: Tell us about how Galooli integrates fleet management into a holistic view of the fuel cycle.

Ronen Barel, CEO, Galooli:

Let me give you an example. We won a tender for fuel monitoring, while another separate tender was for fuel management and fleet management for company vehicles and fuel tankers. When the customer realised Galooli could cover both, he added mobile assets and fuel tankers to the same project. If you use different systems for site monitoring and fleet management, those systems will never speak to each other. When tankers are filled in the fuel station you can compare them to fuel cards. As we know where the cell sites are and where the tankers are, if fuel is dispensed outside the site areas, it means someone is doing something wrong. Similarly, if some of the fuel is kept back at the point of delivery, we can see that too.

we are the cheapest on the market because we come from the mobile asset market, where it’s very competitive so costs are very low. Galooli offers high-end technology, but low cost solutions! We can deliver RoI in less than one year

It’s not just the monitoring of fuel tankers that is important. By monitoring the technicians themselves and their company cars, you can control maintenance better by monitoring routes and the speed of vehicles. We can also use personal tacking to monitor guards on site and ensure they’re completing their routes at night.

By using a holistic platform like ours, fuel, maintenance and the working hours of technicians are unified in the same O&M budget.

TowerXchange: What is the typical capital outlay per site to install your system?

Ronen Barel, CEO, Galooli:

There is a joke that whenever you ask an Israeli a question, the answer is “it depends!” It depends on the scope of the implementation, from a basic system on a site to monitor a few assets, to a full system including cameras, our fully integrated access control system, and assets beyond the passive equipment. The cost per site could be “x” or or “3x”!

What I can say is that from our experience, we are the cheapest on the market because we come from the mobile asset market, where it’s very competitive so costs are very low. Galooli offers high-end technology, but low cost solutions!

We can deliver RoI in less than one year. Our last project delivered RoI in six to seven months.