Karam is a manufacturer of personal protective equipment, with their core competency being fall protection. The complete range of products offered by Karam are manufactured in its fully backward integrated operational set-up and today Karam is one of the world’s largest manufacturers of full body harnesses. Based in India, the company has a global footprint in over 50 countries. Karam offers a fine balance between quality and price and hence it’s products finds its way into the markets in Europe, America, Australia, Middle East, South East Asia and Africa. Karam has made significant inroads into developing new products in this field and prides itself on making systems that are idiot proof and theft proof.

TowerXchange: Please introduce us to yourself and your company.

Hemant Sapra, President, Marketing, Karam:

I’ve been with Karam since the inception of the business in 1997. I run the marketing side of the business, my partner Rajesh Nigam runs the technical side - he’s a qualified engineer having graduated from IIT-Kanpur, the number one technical university in India.

Karam started out manufacturing safety nets for people falling from height, then moved on to manufacture safety harnesses and eventually to focus on fall protection and fall arrest. Karam were the first Indian supplier to meet European safety standards in 1999 - all our equipment is tested and certified to the European EN standards by certifying body SATRA in the UK. We now sell into over 50 countries worldwide. The business has grown rapidly from a staff of 10 and US $1m turnover in 1997 to over 2,000 staff and US $40m turnover now.

We offer a complete range of products which can arrest the fall of person who is working at height - anchorages, harnesses, ropes, hooks, carabiners, fall arresters and fall arrest safety blocks.

We started working for telecom companies three years ago. First we studied the market to understand what kind of systems were being used to protect tower climbers, the hazards which still existed, and then did a subsequent gap-analysis. After three years of R&D, we developed systems that could take care of both telecom tower climbers and people climbing ladders to repair rooftops. The system was certified by both European laboratories (as per EN 353-1) and also complies with American standards - where we’re certified by Intertek-USA.

The biggest hazard while working on a telecommunication tower or while erecting the tower is a fall from heights. The user while climbing a ladder can slip and fall sometimes resulting in a fatal accident. Of course the most important thing is the loss of life, but the accidents also cause lost revenue in terms of compensation, legal costs, medical expenses and loss of work. Another related issue is unauthorised climbing on towers which results in theft and which hits the bottom line of the telecom industry.

TowerXchange: What are the major potential hazards tower climbers and other workers at cell sites need to be guarded against, and how can they be protected?

Hemant Sapra, President, Marketing, Karam:

The major hazards are the risk of a fall while working at heights; exposure to RF; electric shocks; attacks by eagles or bees (eagles nests and bee hives are sometimes found on towers); and snake bites.

There are several ways to protect workers at cell sites. First you have to ensure that the worker is medically fit to work at height, with medical certificates from an approved doctor and appropriate insurance. Then the workforce needs to be properly trained on rescue procedures, trained on the correct usage of equipment, and that equipment needs to be regularly inspected.

There is a risk of falls from telecom towers since there is no easy available anchorage on which a worker can secure himself for a safe tie-up. To counter this, Karam offers a vertical fall protection system using a stainless steel cable. While working at height the user wears a full body harness to protect himself from a fall. However the harness is useful only if it is connected to a strong anchor point that can withstand a load of greater than >12kN.

While climbing the user is continuously changing his position thus requiring an anchor which always keeps him connected. This can be achieved by installing a stainless steel cable on the ladder of the tower. A special fall arrest device (fall arrestor) is connected to the harness of the user. The fall arrestor glides smoothly over the stainless steel cable while climbing or descending on the ladder. However in case of a fall the fall arrestor locks on the cable and hence the fall is arrested. The impact is reduced to comfortable levels with the help of a shock absorber installed at the top end of the stainless steel cable. The impact is thus reduced to an acceptable level of less than 6kN. The cable is installed on the ladder with a stainless steel bracket set which is fitted on the top and at the bottom step of the ladder. To provide a reasonable tension to the cable, a tensioning device is connected to the lower end of the system. These systems are highly recommended for the lattice towers which are widely used by the telecommunication industry.

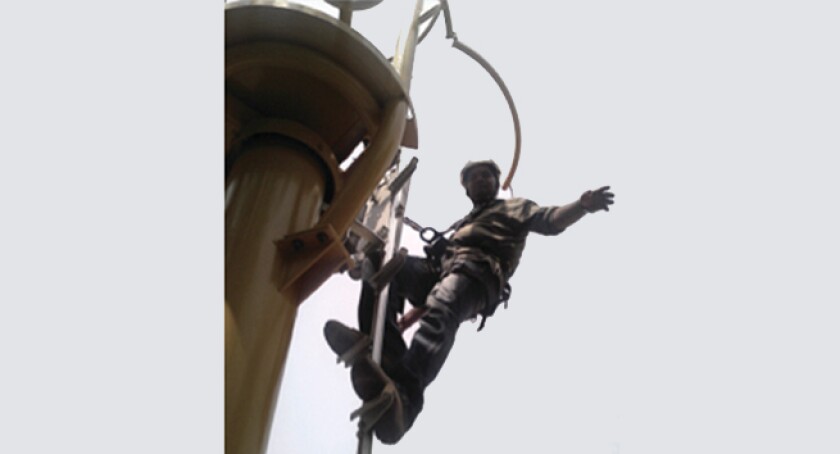

For tubular poles where it is even more challenging to have an anchorage for a safe tie-up, Karam provides an aluminum rail ladder system with steps at regular intervals, connected to an aluminum rail. A special trolley glides smoothly on the aluminum rail while ascending or descending. This trolley is connected to the harness of the user, and works as a safe anchor point for him. In case of a fall it’s special fall arrest design locks the trolley on the aluminum rail and hence the fall is arrested. Again, the trolley has an in-built shock absorbing mechanism which reduces the impact to acceptable levels of less than 6kN.

The other important component of our fall protection system is the specially designed tower harness. The harness holds the user and connects him to the fall protection system. Apart from fall protection, the harness also helps in work positioning using a work positioning lanyard. The work positioning belt of the harness provides lumber support while working at a height. The user also makes use of a twin energy absorbing lanyard for 100% tie off when not connected to the fall arrest system.

A full set of personal protective equipment also includes safety shoes, safety eye wear and protective gloves.

TowerXchange: Tell us your first impressions of the African market when it comes to tower climber safety.

Hemant Sapra, President, Marketing, Karam:

We think the addressable market for us may be 80%+ of Africa’s towers.

Many African towers weren’t designed with tower climbers in mind. There are often no rest points and there aren’t even proper ladders on some towers - climbers have to clamber around like monkeys!

We’ve undertaken a good survey of the kind of safety products being used in Africa, and we feel the quality of products needs to be enhanced. Our products are life-saving - if the safety equipment fails, the tower climber dies - it’s not something we will ever make a compromise on.

However, the problem in Africa is more with the culture than with the safety equipment. Owners of towers have to realise that the first initiative must come from them. They need to see safety as an investment not a cost.

It is critical that tower climbers’ employers develop and document a health and safety system for their workers to follow, and that they monitor the same to ensure compliance. For example, Vodafone have taken the onus to ensure the safety of tower climbers, and their acceptance level of permanent solutions is strong.

Only Europe and the US mandate the use of such safety equipment. There should be laws in every country requiring the use permanent equipment fixed to the tower for the lifetime of that tower.

We’ve started working with dealers in South Africa and Nigeria at a relatively low scale right now, but the African market will be a focus for the next couple of years. African tower operators are starting to look at climber safety. Since we started focusing on Africa in January this year, we’ve already received a couple of big enquiries.

TowerXchange: What are the costs of good safety equipment, on a per site basis? Is there an additional cost in the time taken to fit a harness correctly?

Hemant Sapra, President, Marketing, Karam:

It depends on the height of the tower of course - stainless steel wire rope is expensive. But the average cost to add permanent safety equipment might be around US $1,500 per tower, with a 40m tower costing US £1,300-1,400 and an 80m tower around US $2000.

The time taken to harness up is not a significant factor - it takes 15-30 minutes of training to show a technician how to put on their harness correctly in 60 seconds, and it only takes a few more seconds to ensure they are anchored with a carabiner.

it’s not just about showing the technicians the equipment; it’s about motivating them to use it

TowerXchange: What can Karam do to help change the culture and improve safety standards?

Hemant Sapra, President, Marketing, Karam:

It’s not our job to just provide the equipment, it’s also our job to provide training on the selection of the right harness, the use of that harness and of other safety equipment. And it’s not just about showing the technicians the equipment; it’s about motivating them to use it. Many don’t want to be tied down, but we have to show pictures and video of what can happen if you don’t tie on properly.

TowerXchange: Please tell us how Karam is working with Acsys to integrate access control and safety equipment.

Hemant Sapra, President, Marketing, Karam:

We’re working on a definitive solution with Acsys that will mean people cannot go up a tower unless they are anchored. Tower operators are also concerned about theft of equipment, so we’re working on a first of its kind, innovative design of a ladder where the rungs fold away except when unfolded by authorised climbers with a key.

TowerXchange: Who is your target client, operator, tower co or both?

Hemant Sapra, President, Marketing, Karam:

We target both operators and tower companies - whoever owns the tower. Some of our solutions are fixed assets - part of the tower. In many cases operators will demand certain safety equipment and standards from towercos. The approach might vary between operators and towercos. For example in India towers owned by Vodafone have 100% implementation of permanent fixed systems, whereas on towers they rent from Indus, climbers are being trained to use temporary systems.

Temporary systems require a lower capital outlay in the short term, but as a capital investment permanent fixed systems make sense over three years or more. Tower operators’ preferences often depend on their financial performance.

TowerXchange: Finally, please sum up how you differentiate Karam from your competitors?

Hemant Sapra, President, Marketing, Karam:

We have few competitors, mostly from Europe. Karam are still the only major supplier from Asia certified as per the European standards, and that means we have a cost advantage. For example, Vodafone had a tie up with a French company, but when they contacted Karam for their operations in India, we were able to undercut their European supplier by 70%. We now have 12 years of experience of working with Vodafone, which is how we developed solutions for Vodafone towers in India.

We are exporting to over 50 countries globally - we sell under our own brand in India and in the Middle East, but for all other countries we do private labelling on products and OEM, so we are manufacturing the equipment for most of the big brands around the globe.

Karam is able to meet all tower climber equipment needs in-house. We buy yarn, convert it into webbing and ropes. All our metal and mechanical components are manufactured in-house by our own factory. This ensures customisation as per need while maintaining superior quality in the product at all times.